That switch sounds perfect for my application

By Laurent Kubat & David Têtu | November 05, 2018

Switches are a primary part of the human-machine interface (HMI) for many products, and the quality of the switch is important to the user experience, so selecting the right one is a vital part of the design process. Often an off-the-shelf design from a supplier such as C&K will meet the application needs, while other products require engineering input from C&K to craft the correct switch.

Everything must perform as advertised, on each and every switch, for their entire lifetime. Designers rely on us to ensure that our switches meet their specifications and perform as intended when integrated into the final product.

Feedback, whether tactile or audible, is an important part of any interface design – enhancing the user experience. The automotive industry is particularly keen on this aspect, and defines the sound needed from each and every switch. As a result, C&K has worked on switch sounds since 2009.

To measure switch sound levels, we invested significantly in a semi-anechoic chamber – a protected room that prevents outside sounds from entering and suppresses reflected internal sounds that disturb measurements, allowing sounds of interest to be measured in a ‘free field’ condition.

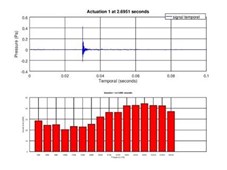

This advanced chamber is qualified to NF EN ISO 3746:2012 and enables our engineers to measure the sound from one of our switches as a standalone product, when mounted on a PCB, or as a switch in a customer application. The chamber allows measurement of the sound spectrum (from 500Hz to 16kHz) and sound level (15dBa to 80dBA). C&K engineers record the sound as a .wav file so it can be further analysed if needed.

To perform sound measurement, the switch (or assembly) is placed 15cm from the microphone, which is attached to a highly accurate Brüel and Kjaer sound level meter. The switch is operated and the sound pressure is recorded and translated into decibels (dB), retaining frequencies between 500Hz and 16kHz that match the range of the human ear.

From this, C&K can work with customers to understand any tweaks that may be needed to meet the (sometimes highly exacting) design spécifications.

In addition to testing and evaluating existing switches and other products, the chamber is also invaluable as part of our R&D process as it gives us the ability to experiment with different materials and configurations. From this we can define and understand the key parameters in a switch design that impact the switch sound – and then rigorously control these parameters to ensure that the specification (and designers’ expectations) are fully met.