SOLDERING AND CLEANING

Most manufacturing and field problems experienced by users of unsealed switches are caused by contamination of the internal switch contacts during soldering and cleaning processes. Switches may become intermittent, especially in low power applications, and may become open during factory testing or later in the field. Care during soldering and cleaning can prevent most process contamination problems encountered.

Contamination can occur in both hand soldering and machine soldering processes. Hand soldering and cleaning are acceptable with properly trained personnel, small diameter solder (.030-.040 in.) and low wattage soldering irons (25-40 watts max.). Solder time is approximately 3 seconds maximum. Do not immerse or spray the unsealed areas of the switches with cleaners during flux removal.

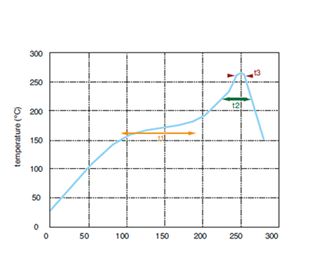

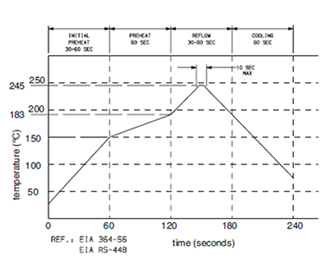

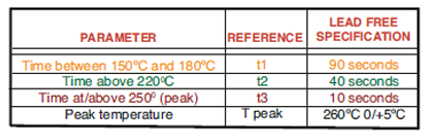

| SMT Reflow Soldering Profile of Reference | Typical SMT Reflow Profile |

|

|

|

|

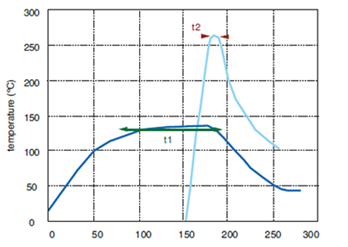

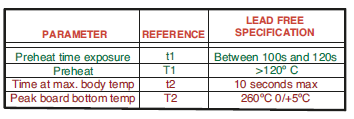

Wave soldering profile of reference

Thermal shock resistance

Thermal profile done in 2 times:

| |

|

Note: Not all of C&K products have been tested to this profile. Please refer to product section for more information.