How to select the best slide switch for your application

By Cathy Zhao | March 24, 2022

Slide switches are one of the older technologies available for selecting, making, or breaking an electrical circuit, however due to their purely electromechanical nature they remain very popular as low cost and reliable means of controlling or interacting with some aspect of a machine or process. Designed to be actuated by the human finger, they are commonly used in industrial, commercial, telecommunication & consumer applications, providing a simple interface between man and machine.

How to select the best slide switch for your application

There are several key areas to consider as follows:

C&K has a very wide portfolio of Slide products, to suit almost any application so some consideration needs to be given to the most important criteria for your design.

Physical size and power switching capabilities

The size of the switch matters as it will take up the expensive PCB space on your devices or equipment. However often the size is determined by the required current rating that you need to switch. For example, a power supply application which will need 3A to 15A of carrying current capacity will typically be larger than a small signal switching slide switch. C&K offers many switches in varying sizes and power ratings to meet most design needs. For the switching of the signal circuits with a rated current of 0.3A, we have the miniature slide of the SS, SK, JS, PCM series to meet the requirement on both smaller size and functionality. On the extremely low current (dry circuit like 10uA current), it will require the Slide switches not only to meet the ultra-miniature on size but also to take care of the designer’s concern over the contact’s normal force requirements and oxidation issue due to the overall size being significantly reduced. The ultraminiature slide switches like JS/PCM/ AYZ (AYZ min size 7.2mm X1.5mm) are designed to address these concerns. On the larger, power side of the Portfolio, C&K’s 1000, L, LP, S and V series all have different features to appeal to different market needs, such as the V series being designed for Power and Line Voltage selector applications.

Number of circuits and positions

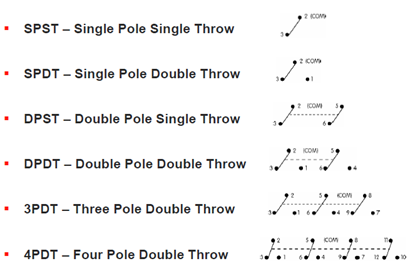

Whether you choose a power or signal Slide switch, C&K offers a wide choice switching configurations within a single switch body (multiple poles, multiple throws) giving designers options to control multiple loads simultaneously. The benefit of this is to give flexibility to customers’ circuit board design, save space while providing multiple circuits control with a single switch. Common to most switch suppliers C&K’s slide switch following a widely used system of acronyms to denote number of Poles (number of circuits) and number of throws (number of positions that a switch can close):

Contact Plating

In general, the contact plating of the Slide switch is either Silver or Gold plated. Siler material is commonly being used for power and signal level switching. Gold can be found and applied in the areas where dry circuit, reduce oxidation, to prevent wear and tear on the contact point. Due to the higher performance requirements on the Slide product, C&K is developing additional Gold-plated version in the existing JS, AYZ and PCM to meet such demand.

On slide switches, the usage of lubricant could impact the characteristics such as conductivity, working temperature, arc suppressing effectiveness, operating force, haptics, mechanical and electrical life. Due to no industry standard, it is a big challenge for Engineers to think over how to well balance among the characteristics of grease including lubricity, adhesion, broad temperature compatibility, oxidation resistance, and compatibility to the plastic material. C&K has spent great efforts on strengthening the capability of lubrication evaluation used in various product series for different customer applications through our American lab. One success story is combining the use of gold plating and lubricant for one customer on the PCM series in fire alarm for security to greatly improve the performance and another case is JS series for CIPer controller in industrial for one leading customer.

Travel

Another consideration is travel, or how far the actuator is moved when actuating the slide switch. A combination of the height of the actuator, the force required to move the actuator, and the length of travel will fundamentally change the feel, or haptic that the user will experience. C&K has a variety of options to meet your design needs whether that is a higher force, longer travel part for use with gloved hands, or a very, light short travel.

Termination Style

C&K offers a variety of termination options from PCB mount to solder wire connections. The choice is again often limited by size, as actuating a larger slide switch mounted on tiny SMT PCB connections can be difficult to integrate, whilst maintaining a good connection between switch and PCB. For smaller devices where Surface mount termination is a must, a slide switch with SMT J bent termination from the JS series would be a good choice. Offering both PCB space-saving and the high yield production rates. More details can be found here:

Special Requirements

One of C&K’s specialisms is solving customers problems, whether that is advising about switch choice selection or offering a custom solution to meet your design challenge. We have a wide experience with slide switches with C&K having thousands of standard PNs from more than 15 series in the catalogs to satisfy customers’ requirements for specific switch functionality, size, load, and life. All our products can be customized on demand, whether that is by adding a custom actuator height, a specific operating force, upgraded materials for reflow soldering process, or gold plating used in the damp environment that may also contains sulfide. Please contact us to discuss your special requirements with our Engineering team by clicking here.